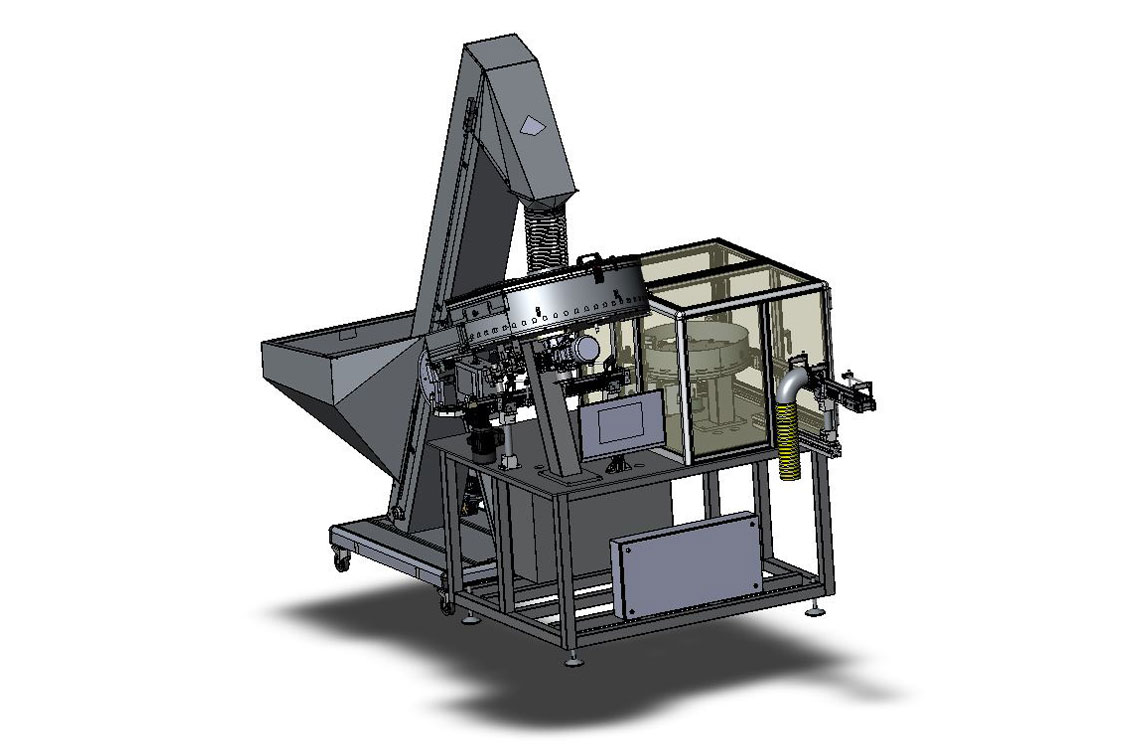

Quality control system: mechanical orientator with camera

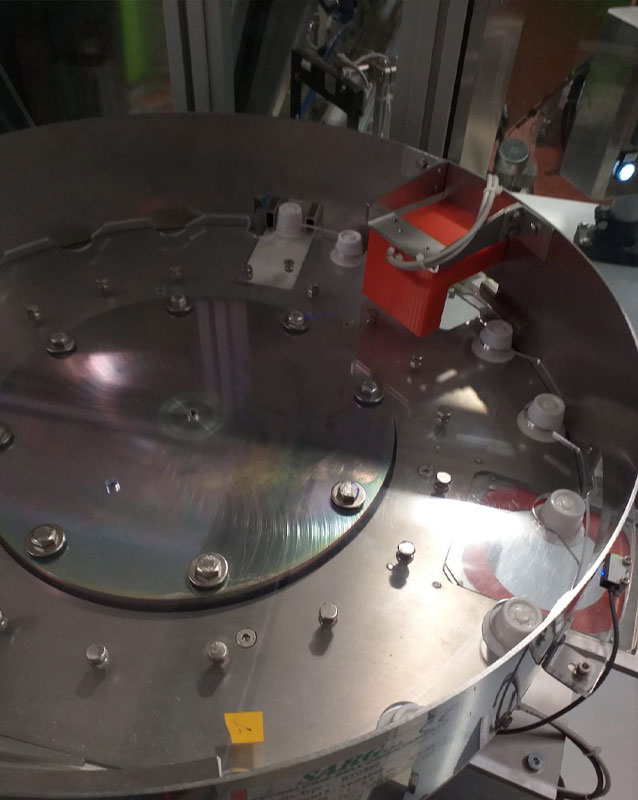

System designed to process most capsules currently on the market. Combined with a vision system, it ensures thorough control of the individual capsule during the process phase. Recommended for high speeds, a customized system enables imperfections to be detected that arose during the moulding phase and the perfect pods and the defective capsules to be conveyed along two different paths. In collaboration with the customer, the imperfection tolerance is defined and the details to be detected so as to supply a guaranteed product to the end user. The plant enables different capsule models to be processed by the same machine owing to the customized format changes.

Consisting of a combined loading hopper, vision system and control panel, the plant is recommended for high/medium speeds.