Project Description

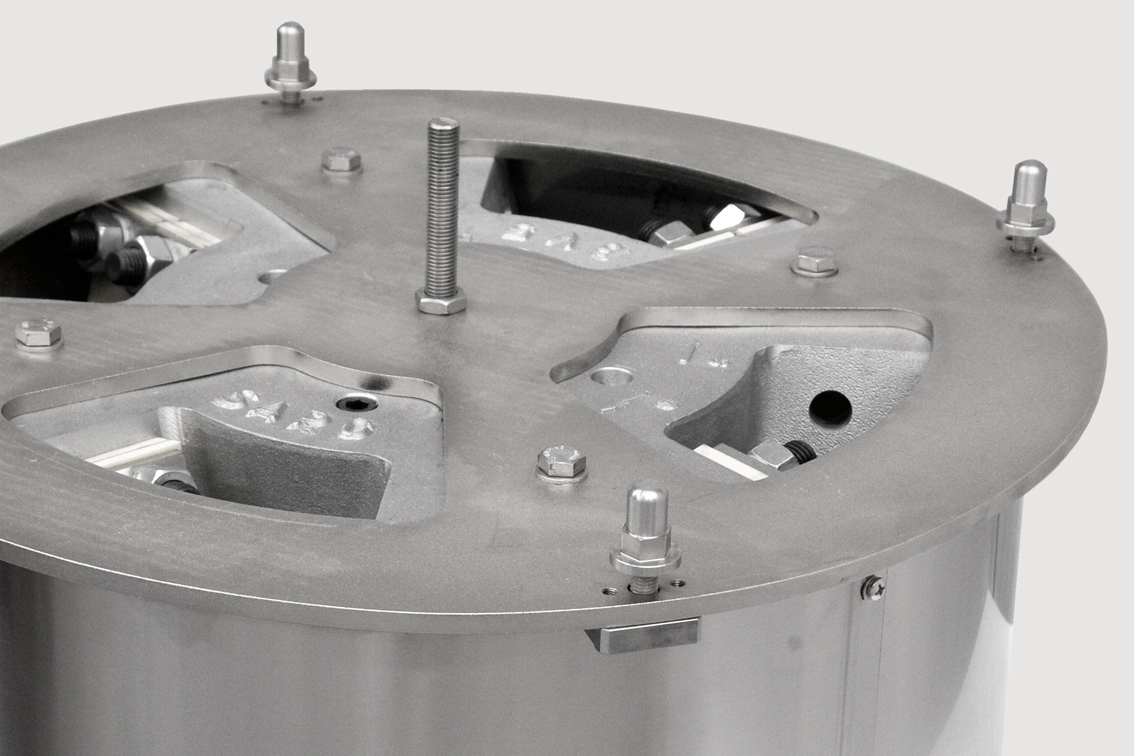

BV circular base unit

Circular vibratory bases or vibratory feeders drive units are composed of an electromagnetic coil which allows the bowl to vibrate, making it possible to orient the parts up to the position needed for interfacing with the machine used by the customer. The parts are normally passing through a series of tooled guides, “traps” or obstructions in the bowl track, referred also to as selection, engineered and handmade in our workshop. The circular vibratory feeder base model BV is suitable for a wide range of uses. Combined with a suitable CI/TC bowls, it is used to feed and orientate plastic, high volume parts as well as small light parts.

Vibratory feeder bowls

The operation of a vibrating feeder conveyor is based on the type of part that needs orienting and the speed required. Circular vibration systems are normally used for lower output speeds . The conical and cylindrical housings of Vibratory feeder bowl is available in a wide range from diameter 160 up to 900 mm and are prepared with different surface treatments: from brush polishing, glass pearl-blasting or polished.

Materials used: stainless steel 304 or 316.

Inner lining of four types:

- Habasit, to facilitate the sliding of the parts (PU)

- Vulkollan, with the same function, but more specifically used for metal parts (High resistance PU)

- Fabric, for the cosmetic sector, where greater caution is required when sliding polished parts.

- Teflon: for delicate parts

Circular drive units

We produce circular drive units in six models BV0, BV1, BV2, BV3, BV4 and BV5 which differ in technical characteristics, e.g. half wave or full wave AC tuned, and dimensions. The standard feeding parameters of our vibrating feeding dishes (V=230V, f=50Hz) can be replaced by alternative parameters upon request. Control units are multifrequency controllers for 50 and 60 Hz AC.

For any information on the specifications of each circular vibratory feeders, please contact us without obligation.