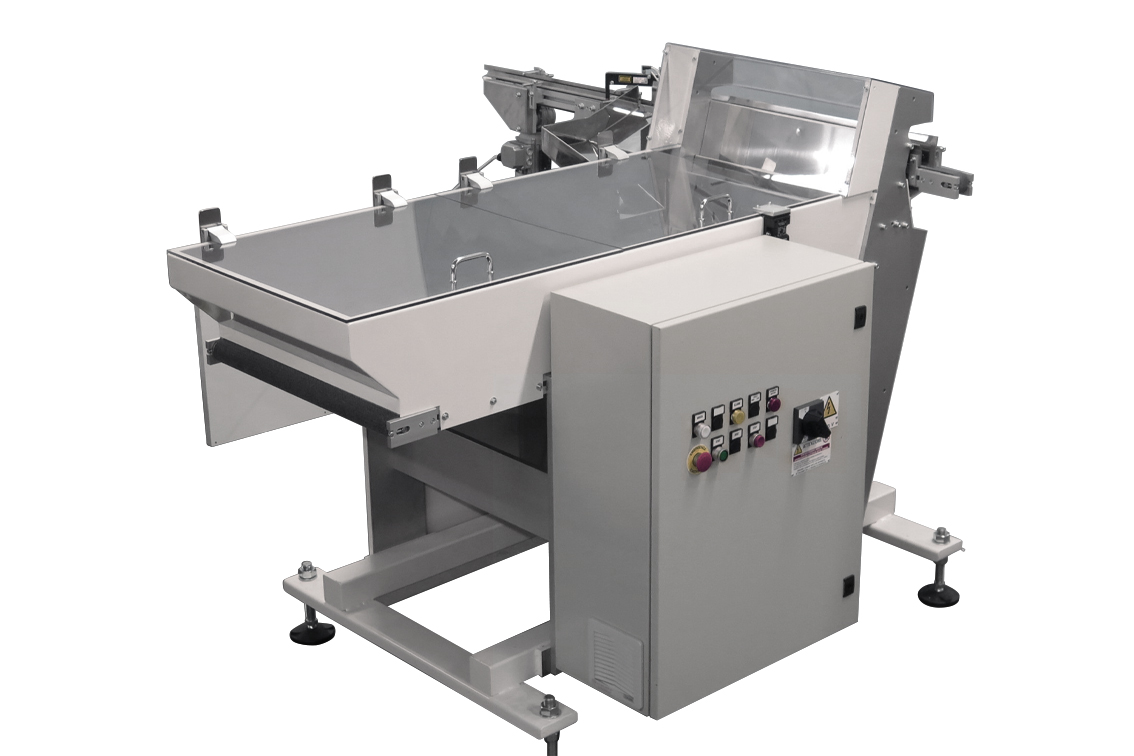

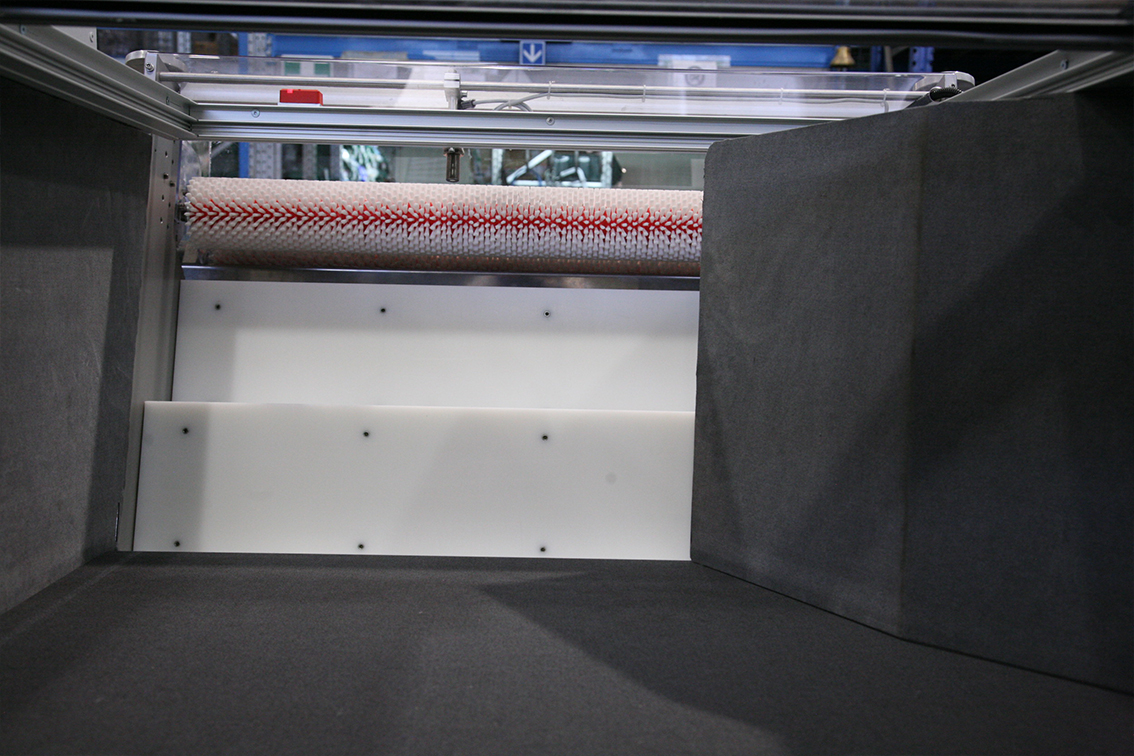

Blade lifter

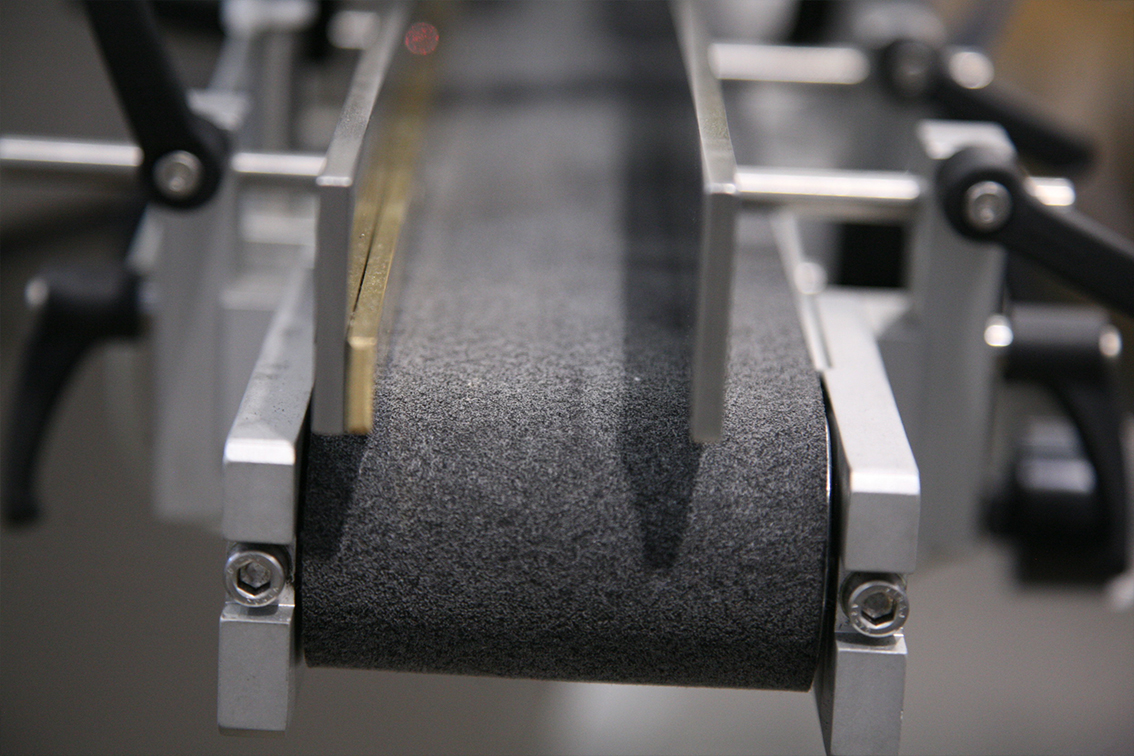

The blade lifter is able to process cylindrical/elliptical parts with particular attention to ensuring that they do not get damaged or spoilt. The structure allows work to be performed at different heights on the basis of the number of blades. Once the items have been processed, the system conveys them on a belt to the customer’s machine for packaging, printing or filling.

A few quick adjustments enable several types of item of different dimensions to be processed.

Recommended for production rates up to 4200 items an hour.

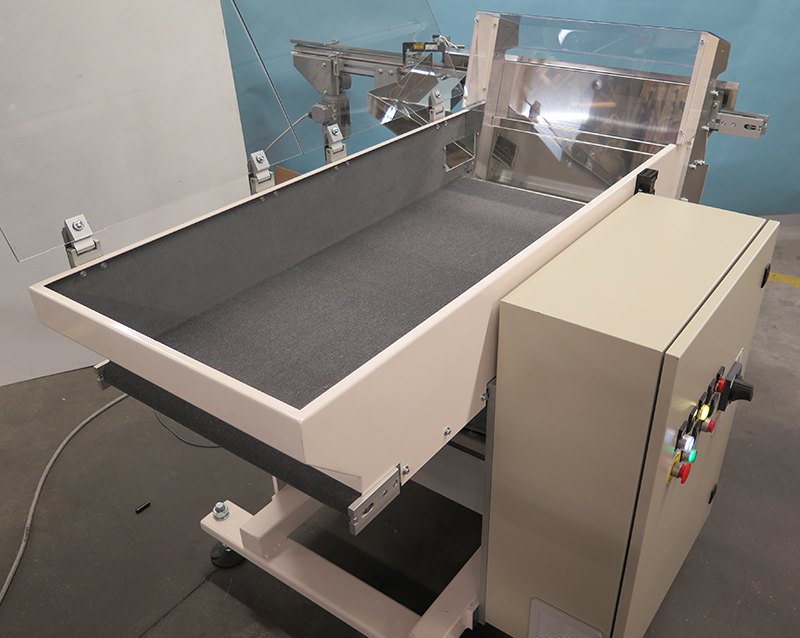

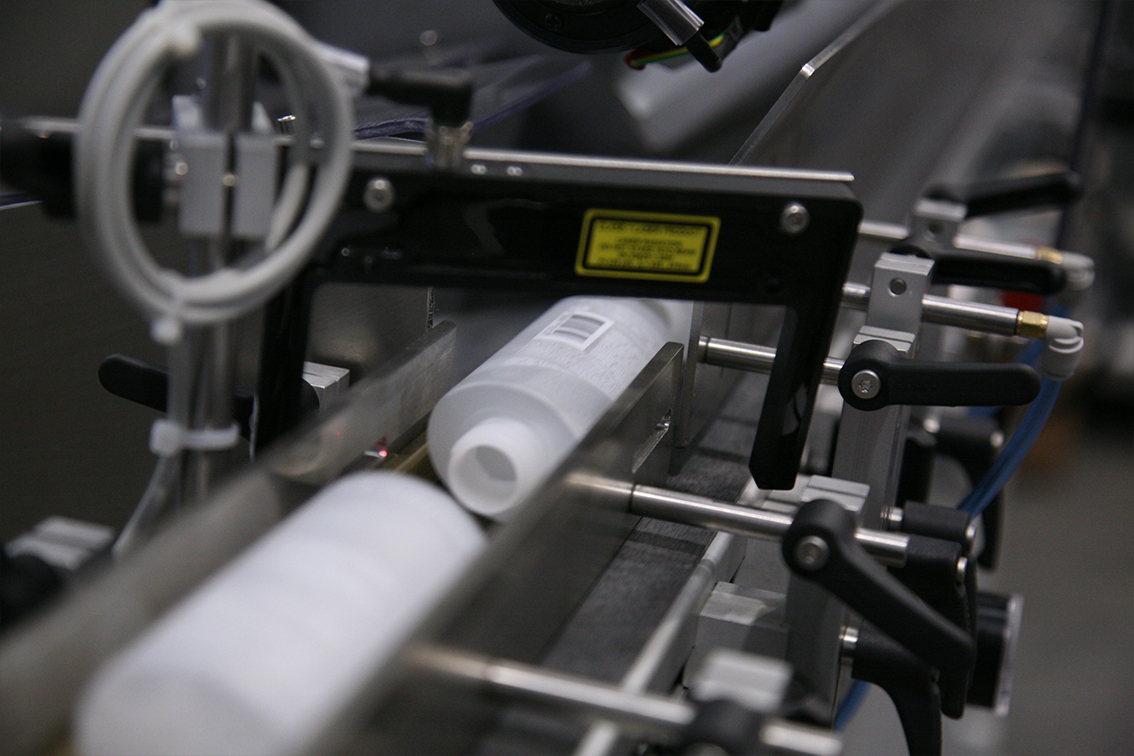

ELCO blade lifter for bottles

Customized solution for bottles of different dimensions to be processed that takes great care to prevent damage or spoiling. Careful customization ensures greater autonomy owing to its combined hopper that can be tailored to customer needs. The structure allows work to be performed at different heights on the basis of the number of blades. Once the items have been processed, the system conveys them on a belt to the customer’s machine for packaging, printing or filling.

A few quick adjustments enable several types of item of different dimensions to be processed.

Recommended for production rates up to 3000 items an hour.